- Empty cart.

- Continue Shopping

What's In A Name? Part 2

There are many different types of saws that can be used in the shop to accomplish various cutting tasks. In the last article, we talked about the more common back, hand and rip saws. This time we will cover how compass, table, and the keyhole and pad saws can be used to augment the saws that you already have and increase productivity.

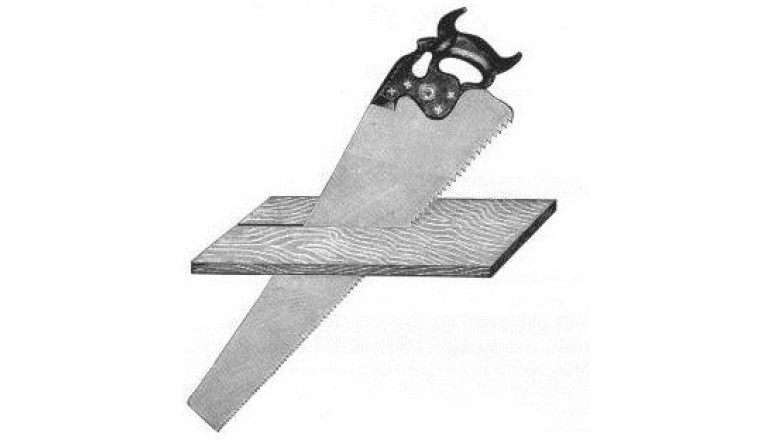

Compass saws are used primarily for cutting out holes on the interior of a board, but their thin tapered blade also allows them to be used to cut a curve on the exterior of a board.

Compass saws are used primarily for cutting out holes on the interior of a board, but their thin tapered blade also allows them to be used to cut a curve on the exterior of a board.

Compass saws were available with blade lengths from 10 to 18 inches. There are virtually as many different types of compass saw construction as there are compass saws. Some have fixed handles with the blade fastened to the handle with two standard brass saw screws. Others have removable blades via a thumb or cam operated lever screw that allows for different pitch and length blades to be used with the same handle. Regardless of the method of attachment, the role of the saw remains the same. The blade on the compass saw is of very heavy gauge material that tapers from about 1 1/2″ to a blunt point. Since the blade has no means of stiffening, and is already thin and prone to bending, the steel is quite a bit heavier than even that encountered on regular handsaws. Since in the course of cutting a circle, the saw encounters both ripping and cross cutting type cuts, the teeth on the compass saw are a combination of the two. While the profile more resembles rip teeth, they are sharpened with a fleam angle like crosscut saw teeth. The result is a saw that can cut in both types of grain, although with less efficiency than if it were one or the other.

Using a compass saw is tedious at best. The thick blade is made thicker by the set of the teeth which allows the saw to move in the kerf it creates. This kerf is quite wide, usually about 3/32″. Since the teeth are a compromise when ripping with or cutting across the grain, cutting with a compass saw is slow work. This type of saw works best  if the blade is kept sharp and properly set. Once the saw begins to dull, it binds very easily, and since the blade is narrow, kinks quite easily. Finding a good compass saw on the old tools market is a challenge. Since they are so easily damaged, finding one with a straight, unkinked blade can be difficult. The good news is that these saws can be straightened with a fair degree of success. Since they are so plentiful, look for one that has a comfortable handle and a blade that is relatively straight. To have a first class compass saw setup, consider finding two compass saws that have similar thickness blades. Sharpen one with true rip teeth, and sharpen the other with true crosscut teeth. When cutting a circle, drill a hole on the inside perimeter of the work and begin cutting with the appropriate saw, the cross cut, or the rip. When the grain starts to change direction, switch to the other saw. Using a pair of compass saws in this manner greatly increases the efficiency of the cut and the surface finish of the work.

if the blade is kept sharp and properly set. Once the saw begins to dull, it binds very easily, and since the blade is narrow, kinks quite easily. Finding a good compass saw on the old tools market is a challenge. Since they are so easily damaged, finding one with a straight, unkinked blade can be difficult. The good news is that these saws can be straightened with a fair degree of success. Since they are so plentiful, look for one that has a comfortable handle and a blade that is relatively straight. To have a first class compass saw setup, consider finding two compass saws that have similar thickness blades. Sharpen one with true rip teeth, and sharpen the other with true crosscut teeth. When cutting a circle, drill a hole on the inside perimeter of the work and begin cutting with the appropriate saw, the cross cut, or the rip. When the grain starts to change direction, switch to the other saw. Using a pair of compass saws in this manner greatly increases the efficiency of the cut and the surface finish of the work.

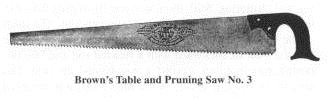

When the word “table saw” is mentioned, an image comes to mind of an electrically operated circular saw mounted in a cast iron frame. Few might realize that a compass type saw used this name long before it was associated with its more dangerous name sake. A table saw looks like a compass saw on steroids. The blade was offered in 12″ to 26″ inch lengths and it was fitted with an open style handle more commonly found on dovetail saws. They were available in both crosscut and rip tooth style configurations. A table saw, as the name suggests, was used to cut along the circumference of a round table, or for any other curved work that needed to be done on the outside of a curve. It is interesting to note, that in some saw catalogs, this saw was more completely termed “Table and Pruning Saw.” While the wider blade does resemble a pruning saw, it is hard to imagine using a saw with such a finely fitted handle outside to trim the apple tree! Since most pruning saws cost roughly the same as table saws, I suspect that the saw manufacturers tried to offer this saw as a two in one type product to entice customers who might be able to use the saw in both roles. It is hard to imagine the cabinetmaker/orchard owner population was that large however. Not surprisingly, these saws are quite rare on the old tools market. They work well in both roles, but like any unsupported saw, should be kept sharp and used with care. A related type of saw used for very different work is the keyhole and pad saw.

When the word “table saw” is mentioned, an image comes to mind of an electrically operated circular saw mounted in a cast iron frame. Few might realize that a compass type saw used this name long before it was associated with its more dangerous name sake. A table saw looks like a compass saw on steroids. The blade was offered in 12″ to 26″ inch lengths and it was fitted with an open style handle more commonly found on dovetail saws. They were available in both crosscut and rip tooth style configurations. A table saw, as the name suggests, was used to cut along the circumference of a round table, or for any other curved work that needed to be done on the outside of a curve. It is interesting to note, that in some saw catalogs, this saw was more completely termed “Table and Pruning Saw.” While the wider blade does resemble a pruning saw, it is hard to imagine using a saw with such a finely fitted handle outside to trim the apple tree! Since most pruning saws cost roughly the same as table saws, I suspect that the saw manufacturers tried to offer this saw as a two in one type product to entice customers who might be able to use the saw in both roles. It is hard to imagine the cabinetmaker/orchard owner population was that large however. Not surprisingly, these saws are quite rare on the old tools market. They work well in both roles, but like any unsupported saw, should be kept sharp and used with care. A related type of saw used for very different work is the keyhole and pad saw.

A keyhole and pad saw is used for cutting interior circles and other shapes that are much smaller than an ordinary compass saw could accomplish, hence the name “keyhole.” The “pad” refers to the handle of the saw which holds the blade. For brevity, we’ll just called them keyhole saws. Some keyhole and pad saws resemble compass saws with the exception that they have very thin delicate blades no more than 3/8 of an inch wide at their widest points. These saws are generally found with 10 to 14 inch blades. Of all the various types of keyhole saws, these are the least desirable since the entire length of blade is exposed during the cutting operation. Since these blades are so fine and thin, they kink very easily if not properly used.

A keyhole and pad saw is used for cutting interior circles and other shapes that are much smaller than an ordinary compass saw could accomplish, hence the name “keyhole.” The “pad” refers to the handle of the saw which holds the blade. For brevity, we’ll just called them keyhole saws. Some keyhole and pad saws resemble compass saws with the exception that they have very thin delicate blades no more than 3/8 of an inch wide at their widest points. These saws are generally found with 10 to 14 inch blades. Of all the various types of keyhole saws, these are the least desirable since the entire length of blade is exposed during the cutting operation. Since these blades are so fine and thin, they kink very easily if not properly used.

A far superior type of keyhole saw incorporates a handle which is slotted all the way through, allowing only the length of blade to protrude that will be needed for the cutting task at hand. It is best to keep the bulk of the cutting activity right up near the handle where it is best supported. The farther away from the handle the blade gets, the more it flexes and the more easily it is kinked. There are several different types of handles that allow the blade to be concealed and extended to the proper length. One less common type is a round wooden handle with a ferrule and thumb screw which is slotted along it’s entire length. Most of these types of saws came equipped with 10 inch blades, about half of which was concealed by the handle in normal storage and use. A far more common type of keyhole saw is one which uses a cast iron handle which is open. The blade slides along a track milled in one side of the handle and is adjusted by a wing nut or cam operated lever. These

A far superior type of keyhole saw incorporates a handle which is slotted all the way through, allowing only the length of blade to protrude that will be needed for the cutting task at hand. It is best to keep the bulk of the cutting activity right up near the handle where it is best supported. The farther away from the handle the blade gets, the more it flexes and the more easily it is kinked. There are several different types of handles that allow the blade to be concealed and extended to the proper length. One less common type is a round wooden handle with a ferrule and thumb screw which is slotted along it’s entire length. Most of these types of saws came equipped with 10 inch blades, about half of which was concealed by the handle in normal storage and use. A far more common type of keyhole saw is one which uses a cast iron handle which is open. The blade slides along a track milled in one side of the handle and is adjusted by a wing nut or cam operated lever. These  saws are slightly less comfortable to use, but are certainly plentiful on the old tools market. Another great virtue of these saws is that since you only use the very end of the blade, when it gets dull or breaks of its own accord during use, it is a simple matter of extending the blade a few more inches and continue cutting. The blades on these saws are almost always filed crosscut, but since the amount of wood removed is small, this is not an inconvenience when doing rip type cuts. While the cutting of circles and other complex curves is not something that is required every day, when the task arises, nothing will rise to challenge better than a properly sharpened compass type saw.

saws are slightly less comfortable to use, but are certainly plentiful on the old tools market. Another great virtue of these saws is that since you only use the very end of the blade, when it gets dull or breaks of its own accord during use, it is a simple matter of extending the blade a few more inches and continue cutting. The blades on these saws are almost always filed crosscut, but since the amount of wood removed is small, this is not an inconvenience when doing rip type cuts. While the cutting of circles and other complex curves is not something that is required every day, when the task arises, nothing will rise to challenge better than a properly sharpened compass type saw.

Photos from 1918 catalog of the Henry Disston & Sons, Philadelphia, PA