- Empty cart.

- Continue Shopping

Saw Filing--A Beginner's Primer

Selecting a Saw Vise What do I need to sharpen my saw? Fortunately, the tools that are required to sharpen a saw are easy to acquire and are not very expensive to get your saw cutting right. The first thing you will need is vise. The saw filing vice has only one job: To hold the saw blade securely and at a comfortable height for filing. The act of filing a thin piece of hardened steel causes a lot of vibration. The saw vice dampens vibration and allows the file to cut. If the saw blade vibrates, it makes it impossible for the file to “bite” into the metal that it is trying to sharpen. This causes the file to skitter across the surface of the teeth, resulting in a dull file and dull teeth. There are many different patents of saw filing vises that were made in the past when saw filing was common. In general, you should look for a vise that has no broken parts with accurately closing jaws. Saw filing vises are very nice that have all their finish and are like new. However, finding vises like this is very difficult. Saw filing vises saw hard use, and were often stored where they got rusty and abused. Do not be concerned if your vise is rusty. As long as all the parts are present and the jaws close firmly and lock in place, you have a vise that will do the job. If you like, you can always clean your vise up and repaint it. Most saw filing vises are not rare or collector’s items. Some of the companies that specialized in saw filing vises were Disston, Wentworth and Stover. Any vise that meets the above criteria can be used. For those who can’t find a good vise, there is sometimes a selection on this website. In addition, making a saw filing vise out of wood is a relatively easy task. There are many plans which spell out how to make a properly functioning vise.

Some Thoughts on Making a Saw Vise There are some common attributes that you should consider if you decide to make a saw filing vise. In general, most of these vise plans work in a shoulder vise and are nothing more than two pieces of wood that are hinged at the bottom. Both pieces have stock removed inside the jaws to accommodate the thickness of the blade. They also have the top of each half of the jaw beveled to 45 degrees, so that when the vise is closed it is easier to file the teeth. You should make the vise as long as you can. Ideally, the vise should be as long as the saw that you intend to file. The one advantage that a craftsman made wooden vise has over an iron one is that the entire side of the saw can be sharpened without moving it. In addition, the inside of the jaws should be slightly hollow in the middle. By doing so, you will ensure that when tightened, the entire length of the blade is firmly gripped.

What Size File to Use The next thing that you need is the proper file for the job. You should seek to buy the highest quality file that you can find. Avoid “bargain” files that are made in India or China. The teeth are not hard or durable enough to sharpen a quality hand saw. While they may seem attractive due to price, they will only waste your time and money. I use Nicholson brand files which are available in the maintenance section of this web site. You should seek to use the right size file for the job. In general, saw filing files common is four tapers: Regular, Slim, Extra Slim and Double Extra Slim. There is a lot of mystique and confusion about what size file to use for a certain size saw tooth. The bottom line is that you should use the file which is not too big or too small. You should be able to easily see the teeth when you are filing. In addition, when each edge of the file is used, there should be no significant over or underlap among the three edges. If you use a file that is too small, you will use the same middle section of each face, which will be dull right where you need it to be the sharpest. Near the middle of each face is where the cutting edge of the teeth is sharpened. If you use a file that is too big you will not be able to see the teeth. Also, larger files do not come to as sharp an edge as smaller files. If you compare the edge of a 7″ file with a 4″ file, you will see that the edge of the 7″ file has almost a 1/32″ “flat” on the edge. Compare that to the edge saw of the 4″ file. It comes to almost a knife edge. It is no accident that shorter files as used to file smaller teeth. If all this in confusing, don’t worry. Just use the files that are recommended in the table below and you will be all set.

| 8″ Regular Taper | |

| 6″ Regular Taper |

5-5.5 |

| 7″ Slim Taper | |

| 6″ Slim Taper | |

| 6″ XSlim Taper | |

| 6″ 2XSlim Taper | |

| 4″ 2XSlim Taper |

File Handles and A Place to File The next thing that you will need is a proper handle for the file that you are using. Do not attempt to file a saw grasping the file by the bare tang. You risk stabbing your palm with the tang if you do so. In addition, it causes the fingers of the hand that are grasping the end of the file to become very fatigued. If you have a lathe, you may enjoy making some handles to fit the various files in your shop. I offer a very convenient high quality handle in the maintenance section of the web site. It has a hardened die which actually threads on to the soft file tang. This causes the file to be securely gripped by the handle, providing maximum safety and comfort. The last thing that you will need is a work area that is properly lit and of the right height. You can’t have enough light when filing saws. However you choose to light your work area, you should be careful not to causes glare on the teeth. By moving various floodlights around the work area, you can find a combination that is right for you. Finally, you should adjust the height of your saw vise so that the angle that is formed by your upper arm and forearm is more of less 90 degrees when you are actually filing a saw. If the vise is too high or low, it will become tiring and causes inefficient work. The time taken to properly set up you filing area will make all the difference in whether you enjoy the process of sharpening your saw, or whether you view it as drudgery.

Different Types of Teeth What are the differences between crosscut and rip teeth? There are two basic types of saw teeth on modern western style handsaws. By western, I mean saws that cut on the push stroke. Crosscut teeth, as the name implies, are used to cut a piece of wood across the grain. Rip teeth are used to cut a piece of wood along the grain. We’ll discuss each in turn.

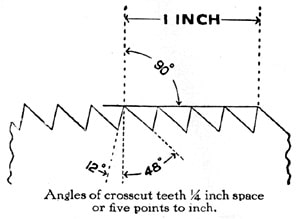

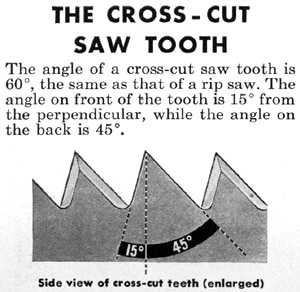

Crosscut teeth are by far the most complex of the two types of saw teeth. Crosscut teeth can be found in sizes from 5-16 points per inch (ppi) with 7-10 being the most common. If you look at the diagrams to the right, you will see that each crosscut tooth is a perfect 60 degree angle. It is no accident that all saw filing files are 60 degrees as well. There are several angles that you will have to keep in mind when thinking about crosscut teeth. The first is the rake angle. By rake, I am describing how much the cutting edge of the saw tooth is sloped back from perpendicular. The most common rake angle is 15 degrees. In general, the steeper the rake angle, the more aggressive the saw will cut. However, saws with steeper rake angles are also more difficult to start. I find that anything from 12-15 degrees is best. I tend to file my saws closer to 12 degrees, as I have no lack of experience in getting a saw to start cutting. If you are a beginner, you may find that a 15 degree rake is more comfortable. As you gain experience, experiment with different rake angles until you find one that you prefer.

Crosscut teeth are by far the most complex of the two types of saw teeth. Crosscut teeth can be found in sizes from 5-16 points per inch (ppi) with 7-10 being the most common. If you look at the diagrams to the right, you will see that each crosscut tooth is a perfect 60 degree angle. It is no accident that all saw filing files are 60 degrees as well. There are several angles that you will have to keep in mind when thinking about crosscut teeth. The first is the rake angle. By rake, I am describing how much the cutting edge of the saw tooth is sloped back from perpendicular. The most common rake angle is 15 degrees. In general, the steeper the rake angle, the more aggressive the saw will cut. However, saws with steeper rake angles are also more difficult to start. I find that anything from 12-15 degrees is best. I tend to file my saws closer to 12 degrees, as I have no lack of experience in getting a saw to start cutting. If you are a beginner, you may find that a 15 degree rake is more comfortable. As you gain experience, experiment with different rake angles until you find one that you prefer.

All About Fleam The second angle that you will need to know about is called the fleam or bevel angle. If you look closely at a properly files crosscut tooth, you will discover that each tooth is shaped like a lance on the edge. This is due to the fleam angles on each tooth and is what makes crosscut style teeth more challenging to file. To understand why fleam is important, it is necessary to understand how a crosscut tooth actually works to cut wood.

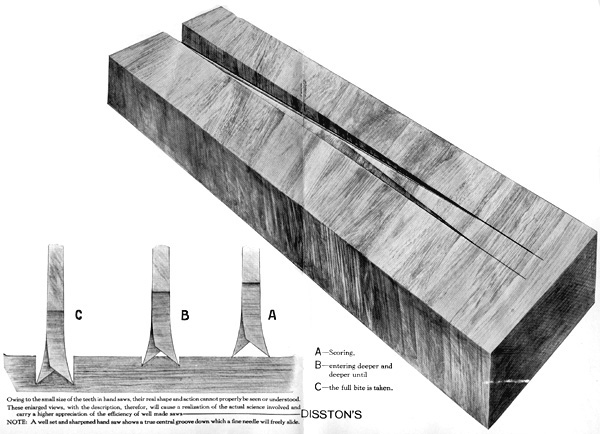

If you think about it, wood is basically a bunch of fibers that are grouped together. These fibers are what is referred to as the “grain” of the wood. To cut them efficiently, the saw teeth act like a series of knives which cut the fibers on either side of the blade. In doing so, the teeth create a channel which is slightly wider than the width of the saw blade. The tips of the crosscut teeth start the work by scoring the wood fibers on either side of the blade. As the cut gets deeper, the front edge of the teeth which are shaped like the edges of a knife, actually pare away at the waste that remains in the center of the cut. The result is saw dust, which is carried out in the gullets of the saw teeth. The gullets are the deep spaces between the cutting edges of the saw teeth. Examine the illustrations to the right to understand the function of the various parts of the cross cut tooth.

If you think about it, wood is basically a bunch of fibers that are grouped together. These fibers are what is referred to as the “grain” of the wood. To cut them efficiently, the saw teeth act like a series of knives which cut the fibers on either side of the blade. In doing so, the teeth create a channel which is slightly wider than the width of the saw blade. The tips of the crosscut teeth start the work by scoring the wood fibers on either side of the blade. As the cut gets deeper, the front edge of the teeth which are shaped like the edges of a knife, actually pare away at the waste that remains in the center of the cut. The result is saw dust, which is carried out in the gullets of the saw teeth. The gullets are the deep spaces between the cutting edges of the saw teeth. Examine the illustrations to the right to understand the function of the various parts of the cross cut tooth.

Practical Fleam Angles

In the illustrations to the left and right, the presence and absence of fleam can be seen in dramatic fashion. To the left, we see a typical section of crosscut teeth. Notice how each tooth comes to a “point”. Each point is a result of the tooth being bevel filed from each direction. The beveling is what is called fleam and makes a crosscut saw work. Since each crosscut tooth has fleam, crosscut teeth, when viewed from the edge, as can be seen at the left, appear as two rows of knives. It is possible, due to this effect, to actually slide a needle between the two rows. This is supposed to be a test of a properly filed and set crosscut saw. In reality, even a poorly filed crosscut saw will pass this test, as long as it is properly set and the teeth are of the same height.

In the illustration at the right, we can see a typical section of rip teeth. Note that each tooth is flat on the top, like individual sets of chisels. Due to the absence of fleam, no “valley” is present as in crosscut teeth.

Like anything, there are some compromises which determine what fleam angle to use. For general use, 20 degrees is best. The higher the fleam angle, the more delicate the edge of the saw tooth will be. The more delicate the saw tooth, the quicker it will dull. However, a steeper fleam angle, like 24 degrees, works great if you work primarily in soft woods free of knots. The cut will be very quick and the result smooth. For lower fleam angles, like 15 degrees, you will have an edge that is more durable, but producing a finish that is rougher. In addition, the saw will be slightly harder to push with a lower fleam angle. Finally, there is one practical consideration to keep in mind when considering fleam angle. Smaller teeth, 12 and up, are harder to file the higher the fleam angle. Since they are so small to start with, not much is gained by using a high fleam angle like 24 degrees. For ease in filing, I use a fleam angle of 15 degrees on the smaller teeth that I file.

In the illustrations to the left and right, the presence and absence of fleam can be seen in dramatic fashion. To the left, we see a typical section of crosscut teeth. Notice how each tooth comes to a “point”. Each point is a result of the tooth being bevel filed from each direction. The beveling is what is called fleam and makes a crosscut saw work. Since each crosscut tooth has fleam, crosscut teeth, when viewed from the edge, as can be seen at the left, appear as two rows of knives. It is possible, due to this effect, to actually slide a needle between the two rows. This is supposed to be a test of a properly filed and set crosscut saw. In reality, even a poorly filed crosscut saw will pass this test, as long as it is properly set and the teeth are of the same height.

In the illustration at the right, we can see a typical section of rip teeth. Note that each tooth is flat on the top, like individual sets of chisels. Due to the absence of fleam, no “valley” is present as in crosscut teeth.

Like anything, there are some compromises which determine what fleam angle to use. For general use, 20 degrees is best. The higher the fleam angle, the more delicate the edge of the saw tooth will be. The more delicate the saw tooth, the quicker it will dull. However, a steeper fleam angle, like 24 degrees, works great if you work primarily in soft woods free of knots. The cut will be very quick and the result smooth. For lower fleam angles, like 15 degrees, you will have an edge that is more durable, but producing a finish that is rougher. In addition, the saw will be slightly harder to push with a lower fleam angle. Finally, there is one practical consideration to keep in mind when considering fleam angle. Smaller teeth, 12 and up, are harder to file the higher the fleam angle. Since they are so small to start with, not much is gained by using a high fleam angle like 24 degrees. For ease in filing, I use a fleam angle of 15 degrees on the smaller teeth that I file.

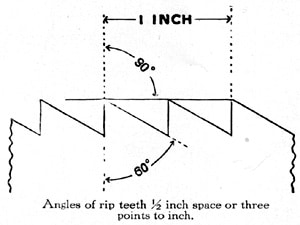

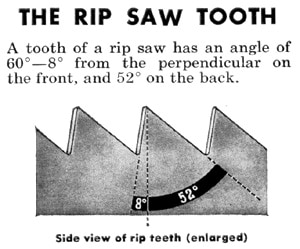

Rip Tooth Geometry Rip Teeth are the easiest type of saw teeth to file, since they do not have any fleam. Rip teeth occur in pitches from 4-7 ppi on hand saws, and from 8-16 ppi on back saws. The most common size of rip tooth for a handsaw is 5 1/2 points per inch. Rip teeth are not as common on back saws that you see available for sale, but in certain applications, such as cutting tenon cheeks or dovetailing, they are invaluable.

Rip Teeth, like crosscut teeth are perfect 60 degree angles. However, unlike crosscut teeth, rip teeth have a very steep rake angle, from 0 to 8 degrees. In the beginning of modern hand saw production, all rip saws had teeth with a zero degree rake. Saws with a zero degree rake (tooth edge perpendicular to the edge of the blade) are very aggressive and quick cutting. However, they are challenging to start a cut if you are not an accomplished sawyer. In the early part of the 20th century, most of the saw makers began to relax the rake angle on their rip saws to make them easier to start. Disston choose an 8 degree rake angle as the best compromise between ease of starting the cut and aggressiveness of cut. Since rip teeth are large and easy to file, I recommend that unless you are experienced, you start with a rake closer to 8 degrees, and gradually reduce it until you find the best compromise between ease of cut and speed of cut. I strike a compromise and file most of my rip teeth at 4 degrees, finding it the most comfortable for me.

Rip Teeth, like crosscut teeth are perfect 60 degree angles. However, unlike crosscut teeth, rip teeth have a very steep rake angle, from 0 to 8 degrees. In the beginning of modern hand saw production, all rip saws had teeth with a zero degree rake. Saws with a zero degree rake (tooth edge perpendicular to the edge of the blade) are very aggressive and quick cutting. However, they are challenging to start a cut if you are not an accomplished sawyer. In the early part of the 20th century, most of the saw makers began to relax the rake angle on their rip saws to make them easier to start. Disston choose an 8 degree rake angle as the best compromise between ease of starting the cut and aggressiveness of cut. Since rip teeth are large and easy to file, I recommend that unless you are experienced, you start with a rake closer to 8 degrees, and gradually reduce it until you find the best compromise between ease of cut and speed of cut. I strike a compromise and file most of my rip teeth at 4 degrees, finding it the most comfortable for me.

How Rip Teeth Cut

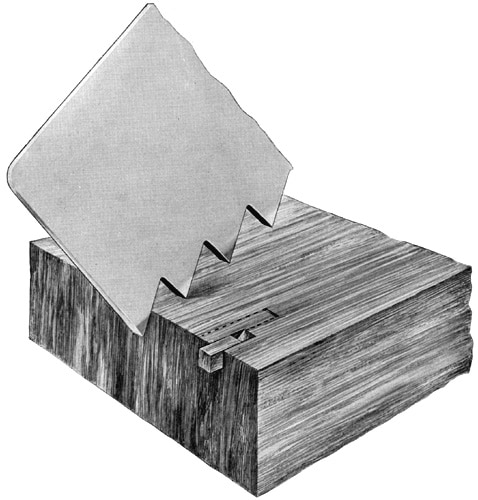

Rip teeth act radically different than cross cut teeth when they are cutting. Since they are flat across the edge, they act similarly to a set of chisels levering out the waste than knives paring it out. If you examine some rip saw dust very closely, you will see that it looks like a bunch of very small plane shavings. In the illustration at the right, you can see the cutting action that rip teeth perform. This is stylized and is to represent the cutting action of just one tooth. But, you can imagine how all the teeth working together would quickly cut a board along its length.

Rip teeth act radically different than cross cut teeth when they are cutting. Since they are flat across the edge, they act similarly to a set of chisels levering out the waste than knives paring it out. If you examine some rip saw dust very closely, you will see that it looks like a bunch of very small plane shavings. In the illustration at the right, you can see the cutting action that rip teeth perform. This is stylized and is to represent the cutting action of just one tooth. But, you can imagine how all the teeth working together would quickly cut a board along its length.

Making a Rake Alignment Jig So, now that you understand the geometry and workings of the two types of saw teeth, it’s time to put that information to good use. You should have a well lit area that is comfortable to you, with a saw vise and file fitted with a proper handle. The most challenging thing in filing saws is to maintain the same angles on each and every tooth that you file. The hardest part in filing is to keep the face of the file properly inclined to keep the rake angle constant. With even a small change in the way you move your wrist, you can increase or decrease the angle by as much as 10 degrees. In saw filing, this is a huge and unacceptable variation. The task is to ensure that the face of the file that defines the rake angle be kept as constant as possible. Allowing the file to follow the angle that is present on the tooth is a recipe for disaster. With repeated filings, the angle will gradually change to the point where the teeth need to be recut rather than refiled.

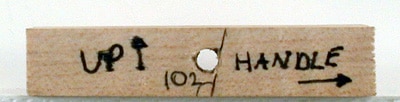

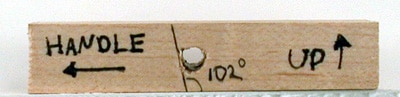

So, the primary concern is to keep the file face constant with respect to the teeth. The easiest way to do this is by making a simple jig out of piece of wood. Take a thin piece of stock, about twice as thick as the diameter at the non-handle end of the file. By diameter, I mean if you scribed a circle that the triangular end of the file would just fit into. Make the piece of wood about 1″ wide and 1 ½” long. Align the grain along the longer dimension. Use a dense piece of wood, like hard maple. Next bore a hole into the edge of each long side. If you are using a drill press, bore it all the way through. Otherwise, bore from each side and meet in the center. The hole should be about the same size as the pointed end of the file. You will be driving the file into this hole, and you want it to securely grip the wood and not slip. The next step will require you to decide on a rake angle. Remember, that good rake angles for crosscut saws are 12-15 degree. Rip saws work best from 0 to 8 degrees. Take an adjustable protractor and set it to the required rake angle. Adjust the beam so it is tilting to the right of 90 degrees by the amount of rake that you have decided to use. Align the bottom of the protractor with the bottom of the block and so the beam just touches the right side of the hole. Scribe a line with a sharp knife. Before going on, mark the right side of the block with the words “Handle” and add an arrow pointing to the right. In addition, mark the very top of the jig with the word “Top“. This will ensure that you always use the right side of the jig and have the top facing up. If you use the wrong side, you will ruin the teeth on your saw.

So, the primary concern is to keep the file face constant with respect to the teeth. The easiest way to do this is by making a simple jig out of piece of wood. Take a thin piece of stock, about twice as thick as the diameter at the non-handle end of the file. By diameter, I mean if you scribed a circle that the triangular end of the file would just fit into. Make the piece of wood about 1″ wide and 1 ½” long. Align the grain along the longer dimension. Use a dense piece of wood, like hard maple. Next bore a hole into the edge of each long side. If you are using a drill press, bore it all the way through. Otherwise, bore from each side and meet in the center. The hole should be about the same size as the pointed end of the file. You will be driving the file into this hole, and you want it to securely grip the wood and not slip. The next step will require you to decide on a rake angle. Remember, that good rake angles for crosscut saws are 12-15 degree. Rip saws work best from 0 to 8 degrees. Take an adjustable protractor and set it to the required rake angle. Adjust the beam so it is tilting to the right of 90 degrees by the amount of rake that you have decided to use. Align the bottom of the protractor with the bottom of the block and so the beam just touches the right side of the hole. Scribe a line with a sharp knife. Before going on, mark the right side of the block with the words “Handle” and add an arrow pointing to the right. In addition, mark the very top of the jig with the word “Top“. This will ensure that you always use the right side of the jig and have the top facing up. If you use the wrong side, you will ruin the teeth on your saw.

Now, flip the block around to the other side, tilt the beam of the protractor an equal amount in the other direction. Position the beam so it just touches the left side of the hole and scribe a line with a sharp knife. When you are done, if you sight through the hole, the lines you scribed should both be tilting the same way when viewed from the same side, not crossing. As before, write the word “Handle” on the left side of the hole, with an arrow pointing to the left. While you are at it, make as many guides as you think you will need for various size files and rake angles.

At this point we are ready to start filing. In general there are 4 steps that might need to be done based on how bad you saw is filed to start with. We’ll discuss each in turn.

Now, flip the block around to the other side, tilt the beam of the protractor an equal amount in the other direction. Position the beam so it just touches the left side of the hole and scribe a line with a sharp knife. When you are done, if you sight through the hole, the lines you scribed should both be tilting the same way when viewed from the same side, not crossing. As before, write the word “Handle” on the left side of the hole, with an arrow pointing to the left. While you are at it, make as many guides as you think you will need for various size files and rake angles.

At this point we are ready to start filing. In general there are 4 steps that might need to be done based on how bad you saw is filed to start with. We’ll discuss each in turn.

Jointing

When a saw is very poorly filed, the teeth become different heights. When this happens, not all the teeth actually cut wood, which is less than optimum. By jointing a saw, we adjust all the teeth to the same height. To do this, place your saw in your saw vise so that about 2″ of blade extends above the jaws. To joint the teeth, you will need a 10″ smooth cut mill file. There are various old and new jointers that were made to do this job, but if you don’t have one, don’t worry. The job is so simple, you don’t really need one. Take the file and lay it on the saw teeth and the heel end of the saw. Grasp the file with both hands, using your forefingers as a guide on each side of the blade. Keeping the file parallel to the floor, rub the file once across the entire length of the blade. If the blade is breasted (slight curve), follow the curve. Now carefully inspect the teeth. If the saw is in proper order, each tooth should have a tiny flat right at the top of the tooth. If some teeth have flats, and others don’t, take another swipe. Continue until all the teeth have been leveled to the same height. If you have one or two broken teeth, DO NOT joint the saw until these teeth have flats on the top. Any saw will work just fine with a few teeth missing. As you repeatedly joint and sharpen your saw, these teeth will gradually emerge. If after a few swipes of the file, it is obvious that your saw is badly out of whack, you should consider having new teeth cut into your saw by a sharpening shop. If no shops are near you and you need this work done, please visit our website where we offer professional saw doctoring services.

When a saw is very poorly filed, the teeth become different heights. When this happens, not all the teeth actually cut wood, which is less than optimum. By jointing a saw, we adjust all the teeth to the same height. To do this, place your saw in your saw vise so that about 2″ of blade extends above the jaws. To joint the teeth, you will need a 10″ smooth cut mill file. There are various old and new jointers that were made to do this job, but if you don’t have one, don’t worry. The job is so simple, you don’t really need one. Take the file and lay it on the saw teeth and the heel end of the saw. Grasp the file with both hands, using your forefingers as a guide on each side of the blade. Keeping the file parallel to the floor, rub the file once across the entire length of the blade. If the blade is breasted (slight curve), follow the curve. Now carefully inspect the teeth. If the saw is in proper order, each tooth should have a tiny flat right at the top of the tooth. If some teeth have flats, and others don’t, take another swipe. Continue until all the teeth have been leveled to the same height. If you have one or two broken teeth, DO NOT joint the saw until these teeth have flats on the top. Any saw will work just fine with a few teeth missing. As you repeatedly joint and sharpen your saw, these teeth will gradually emerge. If after a few swipes of the file, it is obvious that your saw is badly out of whack, you should consider having new teeth cut into your saw by a sharpening shop. If no shops are near you and you need this work done, please visit our website where we offer professional saw doctoring services.

Shaping

Now it is time to closely inspect the teeth. You should look to see if the rake angle of the teeth match the angle that you have decided on. In addition, look to see if some teeth have much bigger flats than others. If the rake angle is really far off, or some teeth have much larger flats than others, you will need to reshape the teeth on your saw. Place your saw in the vise so the gullets of the teeth clear the jaws by about 3/32″ of an inch. Put the saw in the vise so the handle faces the right and the toe of the saw faces the left. Fit your file with a proper handle. Next insert the tip of the file in the alignment jig that you made to go with that file. Find the side that has the line that tilts to the right. Insert the end of the file in the hole so that one of the flat sides of the file is parallel to the scribed line. This will ensure that you maintain the proper rake angle.

When reshaping the teeth, you should strive to make all the teeth the proper height and with a consistent rake angle. As can be seen at the right, I like to start at the heel and of the saw and work to the left. There are only two things that you have to remember in this operation. The first is that you need to keep the alignment jig parallel to the top of the saw blade at all times. By doing so, you ensure that you have a uniform rake angle. Since the block is much wider than the tip of the file, this is relatively easy to do. The second is that you need to look at each pair of teeth as you file, and slightly press the file toward the tooth with the larger flat. For instance, you will start in the first gullet between the first two teeth. If the flats on each tooth are the same size, press the file straight down and push forward while keeping the alignment jig parallel to the blade. You should take as many passes with the file as you need to reduce the flat on each tooth by half. You will get the next half when you move over one tooth. If the flat on one side is much larger than the adjacent flat, press the file slightly toward the larger flat while pushing the file forward. The idea is to cut much more off the tooth that is more out of shape, than the one that is nearly full height. Remember to keep the alignment jig parallel to the top of the saw, take full even strokes and use the entire length of the file. Continue to work to your left until you have to reposition the saw in the vise.

Now it is time to closely inspect the teeth. You should look to see if the rake angle of the teeth match the angle that you have decided on. In addition, look to see if some teeth have much bigger flats than others. If the rake angle is really far off, or some teeth have much larger flats than others, you will need to reshape the teeth on your saw. Place your saw in the vise so the gullets of the teeth clear the jaws by about 3/32″ of an inch. Put the saw in the vise so the handle faces the right and the toe of the saw faces the left. Fit your file with a proper handle. Next insert the tip of the file in the alignment jig that you made to go with that file. Find the side that has the line that tilts to the right. Insert the end of the file in the hole so that one of the flat sides of the file is parallel to the scribed line. This will ensure that you maintain the proper rake angle.

When reshaping the teeth, you should strive to make all the teeth the proper height and with a consistent rake angle. As can be seen at the right, I like to start at the heel and of the saw and work to the left. There are only two things that you have to remember in this operation. The first is that you need to keep the alignment jig parallel to the top of the saw blade at all times. By doing so, you ensure that you have a uniform rake angle. Since the block is much wider than the tip of the file, this is relatively easy to do. The second is that you need to look at each pair of teeth as you file, and slightly press the file toward the tooth with the larger flat. For instance, you will start in the first gullet between the first two teeth. If the flats on each tooth are the same size, press the file straight down and push forward while keeping the alignment jig parallel to the blade. You should take as many passes with the file as you need to reduce the flat on each tooth by half. You will get the next half when you move over one tooth. If the flat on one side is much larger than the adjacent flat, press the file slightly toward the larger flat while pushing the file forward. The idea is to cut much more off the tooth that is more out of shape, than the one that is nearly full height. Remember to keep the alignment jig parallel to the top of the saw, take full even strokes and use the entire length of the file. Continue to work to your left until you have to reposition the saw in the vise.

Keep working until you have adjusted each tooth. As you can see at the picture to the right, the first five teeth (from the heel of the saw) are now properly shaped with a consistent 12 degree rake. They are also all the same height and size. Compare those with the teeth to the left. They are of various sizes, each with a different amount of flatness on top of each tooth.

If the saw is severely out of joint (hey-that’s where that saying comes from), you may have to joint a second time and reshape the teeth over again. If you do, don’t worry, you are learning valuable skills that will make it easier and easier to file any saw. When you are done with this step, take a pass with the jointing file and put just a small flat on the top of each tooth to get ready for the filing step.

Keep working until you have adjusted each tooth. As you can see at the picture to the right, the first five teeth (from the heel of the saw) are now properly shaped with a consistent 12 degree rake. They are also all the same height and size. Compare those with the teeth to the left. They are of various sizes, each with a different amount of flatness on top of each tooth.

If the saw is severely out of joint (hey-that’s where that saying comes from), you may have to joint a second time and reshape the teeth over again. If you do, don’t worry, you are learning valuable skills that will make it easier and easier to file any saw. When you are done with this step, take a pass with the jointing file and put just a small flat on the top of each tooth to get ready for the filing step.

Setting

At this point, some people like to set the saw. I prefer to do it after the filing step. To learn more about setting, see my previous article by clicking here. If you are looking for a saw set, we have a good selection in the maintenance section. We like the Stanley 42X saw set although they are hard to find and in high demand. If you see none for sale, check back often as we are constantly sourcing them. If the saw is in order and did not require much reshaping of the teeth, you may not need to set at all. Most saws have too much set, so by filing some of it away, your saw may be just right. Evaluate the saw by using the guidelines in my setting article. I like to set the saw after it has been filed to ensure that just the right amount is applied. However, you will need at least a little set to be able to properly file your saw. If your saw has been recut, or has had all the set removed by reshaping, take the time to put just a little in now. You should set the teeth the same way that they were set before. That is, don’t try to bend a tooth the other way once it has already been set the opposite way. Doing so usually results in breaking the saw teeth that you try this on.

At this point, some people like to set the saw. I prefer to do it after the filing step. To learn more about setting, see my previous article by clicking here. If you are looking for a saw set, we have a good selection in the maintenance section. We like the Stanley 42X saw set although they are hard to find and in high demand. If you see none for sale, check back often as we are constantly sourcing them. If the saw is in order and did not require much reshaping of the teeth, you may not need to set at all. Most saws have too much set, so by filing some of it away, your saw may be just right. Evaluate the saw by using the guidelines in my setting article. I like to set the saw after it has been filed to ensure that just the right amount is applied. However, you will need at least a little set to be able to properly file your saw. If your saw has been recut, or has had all the set removed by reshaping, take the time to put just a little in now. You should set the teeth the same way that they were set before. That is, don’t try to bend a tooth the other way once it has already been set the opposite way. Doing so usually results in breaking the saw teeth that you try this on.

Filing This is the most complicated part about sharpening a saw. If you had to extensively reshape your saw’s teeth, you almost certainly have all the confidence and enthusiasm you need to make it a success. Position the saw in the vise as before, with the handle to the right. If you had to extensively reshape your saws teeth, remove the file from the alignment block, and use a fresh edge. If the file has done a lot of cutting, it will be no good for the final filing step. Since the alignment block is determining the rake angle, the only other thing that you have to keep in mind is the fleam angle. If the saw is a rip, the fleam angle is zero and you will file the saw straight across. If it is a crosscut saw, you will need to angle the file to establish the fleam. Again, you will want this to be as consistent as possible. It is not as critical as the rake angle, but you should make every effort to make it as uniform as you can. For all around cross cutting, I like to use a fleam angle of 20 degrees. To remind you of this angle, you can do several things. Some people actually make a jig which consists of a ¾” by ¾” square piece of stock. In the center, saw a slot which is 25 degrees to the right of perpendicular. Saw to a depth of about ¼”. Flip the stick over, and file a slot 20 degrees to the left of perpendicular. Finally, place the jig on the saw blade. If the handle is to the left, the fleam jig should point in the direction of the toe. This is very important. If you don’t want to go to the trouble, some people just lay a ruler on the bench behind the saw defining the proper fleam angle. Use whichever method is easiest for you. Finally, we are ready to start to file the teeth. I have done some considerable research on filing saws and have blended that with my own practical experience. There is one important thing that you have to remember when filing either a rip or a crosscut saw. That is, you want to always file toward the toe of the saw. This may seem like a trivial matter, but it is very important. It is much more important in filing a crosscut saw, but it also makes a difference with rip saws as well. I didn’t used to think so, but have changed my mind after further study and experimentation. Why you ask? The answer is simple. Files cut better on the tooth that is bent away from you than they do on the tooth that is bent toward you. If you start on the handle end of the saw, and work toward the toe, you will be filing the back of one tooth that is bent toward you and the front of the tooth that is bent away from you at the same time. Remember, I said that a file cuts much better on teeth that are bent away from you. By placing the handle to the right and filing toward the toe, you will ensure that the best finish is produced on the front of the tooth, and the poorer finish on the back. Since all western saws work on the push stroke, you want to make sure that the front of the tooth is as keen as it can be. The back matters little- the only important thing is that it meets with the front to form a sharp point. Since a crosscut saw works partly by planing the edge of the cut, the front of the tooth does the majority of the work. On a rip saw, the effect is less important, but by maintaining the same approach, and only filing every other tooth, the front of each tooth will get the same treatment as in a cross cut saw. Confused? Don’t be. Just make sure that you always file toward the toe of the saw. OK, place your fleam jig on the saw so that it points toward the toe if you are using one. Starting at the handle end of the saw, which should be on the right. Make sure you use the side of the rake alignment jig that points to the handle toward the right. Place the file in the first gullet that the tooth to the right is bent away from you and the tooth to the left is bent toward you. This may not be the first gullet on the saw, it could be the second. If you look at the cutting edge from above, you will be able to easily tell which is which. This is why it is important to have at least a little set in the saw, so you can keep track of where you are. So, at this point, the tip of the file is in a gullet. You are starting at the handle end and the tooth on the right side of the file is bent away from you, and the tooth on the left side of the file is bent toward you. If you are filing a crosscut saw, the file will be angled to establish the fleam angle. Align the file to be parallel to the fleam guide that you are using. Also keep the file alignment block parallel to the top of the saw. Sound like just too much to keep track of? The first couple times around, it will be. All I can offer is to think before you file each tooth, and after about a dozen teeth, you won’t have to think about it so much and it will become less stressful.

At this point, all the teeth should have flats on the tips which are the same width, so you won’t need to compensate as much as you did when you were shaping the teeth. Making sure that the file is properly aligned, push the file forward. If you are filing a cross cut saw, the saw will most likely make a high pitched shriek. Don’t be alarmed. This is normal. The reason is that the tooth that is bent toward you is vibrating. It is for this reason that it is important to make sure that is the back of one of the teeth not the front. You can reduce the vibration by making sure that the saw is as low in the vise as possible, but high enough that you won’t file into the vise jaws. As in shaping, you should strive to reduce the flat on each tooth by one half. Depending of the size of the tooth, you may only need to take one pass per gullet. Once you’ve reduced the top of each tooth you are filing by half, you have sharpened the front of one tooth and the back of another. Move to the left, skipping one gullet. Since all saws have teeth that have an alternating set, you need to skip a tooth. Don’t worry, when you are done you will flip the saw around and file those as well. As you file, you will realize that you have to bias the file slightly to the left toward the tooth that is bent toward you. Remember, the tooth that is bent away from you files much more easily than the one that is bent toward you. If you don’t compensate for this effect, you will end up with an effect I call, “Big Tooth, Little Tooth”.

Continue filing every other tooth, and work toward the toe of the saw. As you go, slide the fleam jig along if you are sharpening a crosscut saw. Remember to keep the top of the file alignment jig parallel to the top of the saw, bias the file toward the tooth that is bent toward you and take full even strokes with the file. Since you are only removing a small amount of metal to establish the fleam, you will probably not need to use more than one file stroke per gullet to get the tooth sharp. You should inspect the teeth as you go to ensure that the leading edge of the tooth is beveled right down to the edge. Otherwise, there will be a flat spot there left from the tooth reshaping. The leading edge has to come to a sharp edge as much as the top has to come to a point. Again, if you are filing a rip saw, you will not have to worry about this.

At this point, all the teeth should have flats on the tips which are the same width, so you won’t need to compensate as much as you did when you were shaping the teeth. Making sure that the file is properly aligned, push the file forward. If you are filing a cross cut saw, the saw will most likely make a high pitched shriek. Don’t be alarmed. This is normal. The reason is that the tooth that is bent toward you is vibrating. It is for this reason that it is important to make sure that is the back of one of the teeth not the front. You can reduce the vibration by making sure that the saw is as low in the vise as possible, but high enough that you won’t file into the vise jaws. As in shaping, you should strive to reduce the flat on each tooth by one half. Depending of the size of the tooth, you may only need to take one pass per gullet. Once you’ve reduced the top of each tooth you are filing by half, you have sharpened the front of one tooth and the back of another. Move to the left, skipping one gullet. Since all saws have teeth that have an alternating set, you need to skip a tooth. Don’t worry, when you are done you will flip the saw around and file those as well. As you file, you will realize that you have to bias the file slightly to the left toward the tooth that is bent toward you. Remember, the tooth that is bent away from you files much more easily than the one that is bent toward you. If you don’t compensate for this effect, you will end up with an effect I call, “Big Tooth, Little Tooth”.

Continue filing every other tooth, and work toward the toe of the saw. As you go, slide the fleam jig along if you are sharpening a crosscut saw. Remember to keep the top of the file alignment jig parallel to the top of the saw, bias the file toward the tooth that is bent toward you and take full even strokes with the file. Since you are only removing a small amount of metal to establish the fleam, you will probably not need to use more than one file stroke per gullet to get the tooth sharp. You should inspect the teeth as you go to ensure that the leading edge of the tooth is beveled right down to the edge. Otherwise, there will be a flat spot there left from the tooth reshaping. The leading edge has to come to a sharp edge as much as the top has to come to a point. Again, if you are filing a rip saw, you will not have to worry about this.

Flip the saw around, this time with the handle facing the left. Remove the file from the file alignment jig, flip it over and use the other side. Remember to make the cutting edge that you are using on the file parallel with the scribed line on the jig. Flip the fleam angle jig over, and place it on the saw. It should still point away from the handle and toward the toe of the saw. As before, you will sharpen toward to toe of the saw. You will sharpen every other tooth as before, biasing the file toward the tooth that is bent toward you. The only difference is that the tooth that is bent away from you will be on the left, and the tooth that is bent toward you is on the right. Continue along the saw, making sure that all the jigs are properly aligned, and that you bring each tooth to a complete point. Once you have done half a dozen teeth, check the saw for sharpness. If it is sharp, it should “grab” the skin of you palm. Also ensure that the leading edge of each tooth is completely beveled to a sharp edge. Continue along, repositioning the saw in the vise as required.

Flip the saw around, this time with the handle facing the left. Remove the file from the file alignment jig, flip it over and use the other side. Remember to make the cutting edge that you are using on the file parallel with the scribed line on the jig. Flip the fleam angle jig over, and place it on the saw. It should still point away from the handle and toward the toe of the saw. As before, you will sharpen toward to toe of the saw. You will sharpen every other tooth as before, biasing the file toward the tooth that is bent toward you. The only difference is that the tooth that is bent away from you will be on the left, and the tooth that is bent toward you is on the right. Continue along the saw, making sure that all the jigs are properly aligned, and that you bring each tooth to a complete point. Once you have done half a dozen teeth, check the saw for sharpness. If it is sharp, it should “grab” the skin of you palm. Also ensure that the leading edge of each tooth is completely beveled to a sharp edge. Continue along, repositioning the saw in the vise as required.

Finished!

When you have completely finished filing both sides of the saw, all the teeth should be nice and uniform. If you filed a rip saw, all the teeth will appear to be the same size. However, if you were filing a crosscut saw, you will notice that the teeth appear to be different sizes. In the partially filed saw at the left, you will notice that the first, third, fifth, seventh and ninth tooth (from the left) all appear to be slightly larger than the tooth to their immediate right. Don’t worry, it is merely an illusion caused by the effect of fleam. Since you are looking at the backs of some teeth (non-fleam side) and the fronts of others (fleam side), the teeth appear to be different sizes. However, if you hold it up to the light, you will notice that once you negate the effects of fleam, the teeth are the same size.

Congratulations! You have completely sharpened the entire saw. You are on the road to learning a skill that most think is too hard or too complicated to master. Inspect each tooth. They should all come to a complete point and be all the same height. The final thing that you need to do is to lightly dress each side of the saw with a fine oil stone. I prefer a medium India. Do not allow it to contact the point of the teeth. Rub it along the side of the saw, removing the filing burrs as you go. This is an important step. It is most easily done by laying the saw flat on a table and placing the stone flat on the blade with the edge overhanging the teeth. Use a small amount of oil and rub lightly two or three times the length of the blade on each side.

When you have completely finished filing both sides of the saw, all the teeth should be nice and uniform. If you filed a rip saw, all the teeth will appear to be the same size. However, if you were filing a crosscut saw, you will notice that the teeth appear to be different sizes. In the partially filed saw at the left, you will notice that the first, third, fifth, seventh and ninth tooth (from the left) all appear to be slightly larger than the tooth to their immediate right. Don’t worry, it is merely an illusion caused by the effect of fleam. Since you are looking at the backs of some teeth (non-fleam side) and the fronts of others (fleam side), the teeth appear to be different sizes. However, if you hold it up to the light, you will notice that once you negate the effects of fleam, the teeth are the same size.

Congratulations! You have completely sharpened the entire saw. You are on the road to learning a skill that most think is too hard or too complicated to master. Inspect each tooth. They should all come to a complete point and be all the same height. The final thing that you need to do is to lightly dress each side of the saw with a fine oil stone. I prefer a medium India. Do not allow it to contact the point of the teeth. Rub it along the side of the saw, removing the filing burrs as you go. This is an important step. It is most easily done by laying the saw flat on a table and placing the stone flat on the blade with the edge overhanging the teeth. Use a small amount of oil and rub lightly two or three times the length of the blade on each side.

Test Cutting The final step is to see how it cuts. Take a square and mark a piece of wood with the proper type of cut for the saw you have just filed. Draw back slightly to start the cut. Since the saw is very sharp, it will be harder to start than it will be after it has been used for a while. Once the cut is started, take long full strokes the entire length of the saw blade. If the saw is properly filed and set, the saw should slice through the cut with a minimum of effort. If the saw rattles as the toe comes out of the cut, the saw has too much set. Continue to stone the edges and equal amount until the rattle disappears. In extreme cases, you may have to lightly peen each tooth to remove some of the set. This is the main reason I like to apply the set after I’m done filing. You ensure that you apply only what you need to make the saw cut properly. The saw should follow the line with a minimum of correction. If the saw drifts from the line, you have one of two problems (maybe both if you are really unlucky). Either the saw has more set on one side than the other, or due to improper filing, the teeth on one side are taller than those on the other. First sight down the edge of the blade. If the teeth are different heights, you will be able to see two ridges, one lower than the other. The only cure for this is to refile the saw. However, more often than not, it is purely due to one side being overset. Stone the side of the saw again that is on the side of the drift. That is, if it is drifting to the left, crossing the line you are following, stone that side of the saw. Also, saws sometimes cut unevenly if some of the burr remains from filing. Make sure that it is all removed by stoning. Once the final tuning of you saw is complete, it will cut flawlessly. I hope that this treatise will serve as an adequate guide to enable you to learn the art of saw filing. It is a skill learned with patience and attention to detail. If you have those two qualities, with proper practice, you will be able to sharpen any saw that you find in the shop.

Sources Used: Bassler, F.M., Why a Saw Cuts, Henry Disston & Sons, Inc, Philadelphia, PA, 1916 Disston Saw, Tool and File Manual, How to Sharpen a Hand Saw, Henry Disston & Sons, Inc, Philadelphia, PA, 1952 Grimshaw, Robert, Saw Filing and Management of Saws, The Norman Henley Publishing Co., 132 Nassau St, NY, NY, 1912 Holly, H.W., The Art of Saw-Filing, John Wiley, 535 Broadway, NY, NY, 1864 Paquin, Jules, Sharpening Saw–Principles, Procedures and Gadgets, Fine Woodworking Magazine, May 1980 Payson, Harold, Keeping the Cutting Edge: Setting and Sharpening Hand and Power Saws, WoodenBoat Publications, Naskeag Road, Brooklin, ME, 1988 Taintor, C.C., Suggestions on The Care of Saws, Taintor Manufacturing Company, 113 Chamber Street, NY, NY, 1908