- Empty cart.

- Continue Shopping

Henry Disston & Sons Redesign the Hand Saw

Henry Disston & Sons

by Pete Taran

The period from 1927-1930 was one of vast change at the Disston Plant. During this time the entire Disston line was revised and changed drastically. One can only speculate as to the causes for this change. This period in US history is one that is remembered in terms of rampant growth and wild excess. Perhaps the Disston Management team was striving to keep up with the times. Perhaps they saw the lean years ahead that would follow the stock market crash in 1929 and wanted to position the company to survive the troubled economy that lay ahead. Whatever the reason, the handsaw product line was changed forever. In this article, we will investigate what these changes are, and how they differed from the line of handsaws that had been produced between 1840 and 1927 when the changes began.

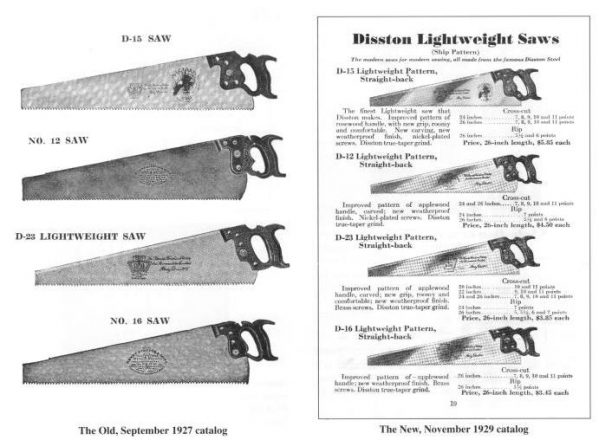

In 1927, we saw the introduction of three new saws that signaled the beginning of the change of the Disston Line. That year Disston introduced the No.12 Lightweight (Ship) Pattern Saw, the D-8 Lightweight (Ship) Pattern Saw and the No. 16 Lightweight (Ship) Pattern Saw. Ship Pattern saws refer to a saw that is very narrow at the point and not as wide at the heel. Typical dimensions are one inch at the point and six to six and one half inches wide at the butt. The idea was to provide for a saw that could cut curves like those required in the construction of ships.

Ship Pattern Saws were not unknown to the Disston line. They had made the No.7 Ship Carpenters’ Saw since 1848, only eight years after Henry Disston founded the company. In addition, they made a ship carpenters’ version of the D100.

Finally, they also marketed the D20 and the D23. They were originally referred to as the D20 Skewback and the D23 Straight Back. In 1927, however, they were redesigned as the D20 and D23 Lightweight. These saws were marketed to carpenters who had to use a saw all day long. By being lighter in weight, they reduced the fatigue that would normally occur from a day of sawing. By modern terms the word “lightweight” brings to mind something that is less than satisfactory when it comes to tools. In this instance though, the term lightweight was used favorably and was well received by the market.

The three saws introduced in 1927 were undistinguishable from their wider bladed counterparts as far as the handle fit and finish are concerned. These saws continued as part of the main Disston line until August 1, 1928. On this date, the line was completdy revised. Many of the specialty saws were dropped. All the saws from this point on would be produced with straight or skewed backs, but the “nib” was dropped forever from straight back saws. The saws offered came in two basic types: regular pattern and lightweight pattern.

The line now consisted of seven lightweight saws: D-15, D-12, D-23, D-20, D-16, D-8 and the D-7. Of particular note is that the “No.” standing for “Number” was dropped for all time. The “D” designation would be used for all handsaws from this point forward. The line also consisted of eight regular pattern saws: D-120, D-115, D-112, D-12, D-16, D-8, D-7 and the D-17. Again, these saws had normal width blades, but they were not as wide as their pre-1928 counterpart.

There were six main features of the new Disston line that were widely advertised when introduction in 1928. These were: Lighter Blades, Narrower Blades, True Taper Grind, Thinner Blades, Stiffer Blades, New Handle Design and Weatherproof Handles.

Saw blades were indeed drastically different from those produced previously. Since the blades were narrower than before, they were in fact lighter. Even the regular pattern saws had slightly narrower blades than their nibbed counterparts. In addition, they were produced with a more aggressive taper grind. Taper ground blades are a uniform thickness along the cutting edge, but tapers in thickness toward the upper tip of the blade. This helps to reduce the amount of set required and provides for a lighter blade. The narrower blade was advertised on the premise that a lighter blade required less effort to use and was therefore superior. Additionally, Disston suggests that they increased the temper to make the lighter blades stiffer and therefore less likely to kink in the cut. A quick strumming of some saws in my collection does in fact yield a higher pitch ring than their older counterparts. A more thorough metallurgical investigation might reveal a more definitive answer to this observation.

Of all the design changes, the newly designed handles is perhaps the most noticeable. The new handles are less graceful than the old ones. Those decorated with wheat carving are done more crudely than before. However, the fit and finish is as high quality as before. Of particular note is what is termed a “cover top” handle which is new starting in 1928. Previously, the handles were slotted from top to bottom and the blade inserted. The edges of the blade on the earlier handles were visible where the blade entered the handle. On the new cover top design, the handle was slotted on a jig that left a curved slot inside the handle. The saw blade was punched from steel that had a corresponding curve where it entered the handle. When viewed from the top, the blade appeared to stop where it entered the top of handle. While the effect was aesthetic, it also was marketed as an improvement in strength. Since the edge of the saw blade inside the handle bore against the slot across the entire width of the blade, it prevented the blade from rocking should the nuts loosen up. This was referred to as “triple anchorage” and was indeed an improvement over earlier saws with dead space between the end of the blade and the handle.

Finally, Disston improved the formula of the finish that it applied to the saw handles. It was a more weatherproof formula that was more durable and resistant to the elements. It was reportedly unaffected by two years exposure to the outside elements. While this may be true, the affect on the steel of a saw that is left in the elements for two years is slightly more problematic.

Hopefully, this article served to educate the reader about a period of vast change in the Disston Plant in the late 1920s. Some would view these changes now as detrimental to the overall quality of the line. However, at the time, they were heralded as modem improvements and were demanded by the market. With the advancement of time, the only certain thing is change and we can only guess as to the reasons behind them.